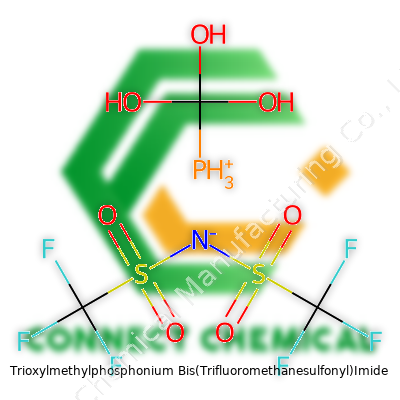

Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide: A Deep Dive

Historical Development

Chemical innovation pushes boundaries, propelled by the pressing needs of science and industry. The story behind Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide traces back to the growing demand for specialized ionic liquids during the late 20th century. Researchers needed salts stable enough for challenging electrochemical environments, yet adaptable across several emerging applications. Decades ago, phosphonium-based ionic liquids entered the scene, constructed to challenge traditional ammonium or imidazolium salts on thermal and chemical stability. Labs in both academia and the private sector experimented with a wave of novel cations and sought out powerful anions like bis(trifluoromethanesulfonyl)imide, prized for its hydrophobicity and resistance to hydrolysis. Industries hungry for greener solvents and next-generation electrolyte materials saw the potential. Over time, the synthesis and use of this compound shifted from small-scale curiosity to a platform in advanced chemistry.

Product Overview

Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide belongs in the family of phosphonium-based ionic liquids. This compound appears as a colorless to pale yellow viscous liquid or powder, depending on storage conditions and purity. Its unique ionic pairing grants it low vapor pressure and remarkable resistance to oxidation. Companies specializing in high-performance materials or custom synthesis often keep it stocked for R&D or niche industrial work. Many chemists encounter this compound when exploring enhanced solvent systems, high-temperature lubrication, or as a platform for further chemical innovation. Its ability to dissolve a range of organic and inorganic materials opens doors for creative problem-solving.

Physical & Chemical Properties

This compound shines in applications that require extremes. With a typical melting point well below room temperature, it remains liquid across a wide thermal range, supporting roles in processes where thermal cycling or heat stability matter. The bis(trifluoromethanesulfonyl)imide anion, known for its bulky, fluorinated structure, confers strong hydrophobic character and suppresses reactivity with water. Its ionic conductivity stands out among organic salts, crucial for electrochemical uses. Viscosity may vary depending on water content or impurities, and density hovers near that of concentrated brine solutions. Trioxylmethylphosphonium cations stabilize the structure, strengthening the resistance to nucleophilic attack and oxidation.

Technical Specifications & Labeling

Market-ready samples usually exceed 98% purity, as even minor impurities can affect conductivity and viscosity. Safety data sheets assign UN numbers recognized by international transport agencies, and manufacturers ensure every container lists hazards tied to both the phosphonium cation and the highly fluorinated anion. Researchers interested in small-scale evaluation rely on detailed specification sheets covering molecular weight, pH in solution (often neutral to mildly acidic), moisture sensitivity, and storage instructions. Packaging follows strict guidelines—opaque, sealed bottles shield contents from light and atmospheric moisture, extending shelf life and minimizing degradation. Barcode tracking and batch numbers help pinpoint origin and any quality assurance issues.

Preparation Method

Laboratories synthesize Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide using a two-step approach. They start by preparing a trioxylmethylphosphonium halide—often through alkylation of phosphine precursors by trioxylmethyl halides under anhydrous conditions. Next, they perform metathesis with lithium or sodium bis(trifluoromethanesulfonyl)imide, generating the target ionic liquid and precipitating out inorganic salts like NaCl or LiCl. Purification involves multiple stages of filtration, washing, and drying under vacuum, scrupulously avoiding water or oxygen that can degrade yield and purity. Specialized glassware and inert atmosphere techniques are standard here, reflecting the sensitivity of the intermediates and final product.

Chemical Reactions & Modifications

Chemists often use Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide as both a reagent and a reaction medium. The phosphonium center displays unique reactivity towards nucleophiles, supporting alkylation and substitution chemistry. The ionic liquid matrix offers a robust environment for promoting catalysis, especially in reactions where metal catalysts risk deactivation by traditional solvents. Its stability against acidic and basic conditions lets scientists explore transformations at both ends of the pH spectrum, including cross-coupling, polymerizations, and advanced separations. Further modifications often focus on tweaking alkyl groups on the phosphonium or changing anion partners to dial in properties like solubility or ionic conductivity.

Synonyms & Product Names

Practical communication in a chemical lab requires precise language, so Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide commonly goes by synonyms like TMPP-TFSI or Trioxylmethylphosphonium NTf2. Catalog listings might abbreviate further or use systematic nomenclature, but researchers recognize these shorthands in both literature and on supply orders. Manufacturers sometimes brand their versions, touting purity or performance advantages, but the core formula remains the same.

Safety & Operational Standards

Handling any ionic liquid, especially those with fluorinated anions, demands diligence. Safety protocols recommend gloves, goggles, and lab coats, as both phosphonium cations and TFSI anions can irritate skin and eyes. Spillage on benchtops or glassware leaves stubborn residues if not cleaned up immediately. Chronic exposure risks rise if ventilation fails—so fume hoods and proper waste containers remain standard. Disposal procedures send remnants to certified hazardous waste handlers, who treat high-fluorine compounds as persistent environmental contaminants. Regulatory frameworks in Europe, North America, and East Asia keep a close eye on use, transport, and documentation.

Application Area

Industries with an appetite for cutting-edge materials value this compound for its diverse properties. In my time working in a collaborative research group, electrochemists pushed ionic liquids into battery and supercapacitor labs, seeking electrolytes that wouldn’t catch fire or corrode electrodes under heavy cycling. Engineers selecting lubricants for microelectromechanical systems noticed the low volatility and thermal resilience. Polymer chemists evaluated its unusual ability to dissolve both polar and non-polar monomers, leading to cleaner reaction profiles and easier purification. Environmental scientists, wanting solvent alternatives that reduce volatile organic compound emissions, looked at these liquids for extraction and separation. Academic curiosity continues to nudge experiments into catalysis, organic synthesis, and even sensor development.

Research & Development

Labs across universities and industry alike keep probing new applications, extending well beyond its established role as a solvent or electrolyte. The challenge remains: balance performance with safety and cost. Computational chemists model behavior at the molecular level, hoping to predict conductivity and stability under new conditions. Interdisciplinary teams screen libraries of phosphonium salts, adjusting substitution patterns to target specific reactions or material interfaces. I’ve seen grant proposals focus on upscaling production, aiming to bring prices down for broader industrial use. There’s a steady buzz of patent activity, particularly where green chemistry or high-performance electronics intersect with these materials.

Toxicity Research

Scientists keep a close watch on potential toxicity. Early studies pointed out that high exposures in environmental settings can disrupt microbial communities and linger in aquatic ecosystems because of the fluorinated tail. So far, acute toxicity in mammals tends to rate lower than related ammonium analogs, but chronic data remain limited. With regulators tightening scrutiny on PFAS and similar chemicals, anyone working with TFSI-based ionic liquids shoulders the responsibility for careful use and disposal. Research groups now routinely conduct longer-term studies, measuring not just LD50 but subtle cellular effects and breakdown products in soil and water. Industry leaders back these studies, realizing their license to operate depends on solid, transparent science.

Future Prospects

Every new chemical invites scrutiny and optimism in equal measure. Expect further breakthroughs in areas ranging from energy storage to next-generation catalysis, but the bar keeps rising for both environmental stewardship and safety documentation. Students and researchers regularly seek deeper insight into structure-property relationships, motivated by energy, cost, and the demand for sustainable alternatives. Funding bodies listen closely to calls for green chemistry, so derivatives that reduce environmental persistence or enhance biodegradation stand to shake up the market. Overall, the future of Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide depends as much on thoughtful handling and innovative applications as on any undiscovered tweak to its structure or synthesis.

Not Just Another Chemical Compound

Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide, often known simply by its shorter trade names in research circles, packs a punch where high-performance electrolytes matter. Its most impactful use shows up in advanced energy storage technology. As someone who has peered at more than a few coin cells on a benchtop and watched the excitement as new battery chemistry changes how the world stores energy, the presence of unique ionic liquids like this one promises real breakthroughs.

Why Ionic Liquids Like This Matter

In the battery world, safety, stability, and efficient ion transport always come up in conversation. Most traditional lithium-ion batteries rely on flammable, volatile solvents that limit design and performance. Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide offers a safer, non-volatile environment. Even at high voltages, it maintains chemical stability, which helps devices operate longer as they deliver steady power. Teams across labs want to push boundaries, chasing longer cycle life and higher capacities, but run into thermal runaway and breakdown if solvent chemistry falls short. Using phosphonium-based ionic liquids raises the safety bar, and that’s real progress.

Electrolytes for Next-Generation Batteries

Engineers building solid-state batteries and supercapacitors aim for fast charging but worry about dendrites and other destructive processes. A good ionic conductor that resists high temperatures and doesn’t catch fire buys time for innovation. Researchers have tested Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide for wider electrochemical windows, showing promising stats in academic journals. Such stability attracts both academic labs and commercial scale-up projects. I've witnessed situations where a single choice in electrolyte sweeps away months of roadblocks. A robust ionic liquid that keeps the electrodes happy transforms progress from small, careful steps into confident strides.

Meeting Demand in Clean Energy

To keep up with the shift toward electric vehicles and renewable storage, companies hunt for electrolytes that won’t degrade under heavy cycling or wide temperature swings. Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide’s chemical structure resists breakdown, even in punishing conditions. As it dissolves lithium salts efficiently, this compound helps push battery architectures past current limits. Not every material survives repeated charging and discharging at high rates, so chemistries like this offer a real path to power electronics, grid storage, or rapid EV charging without risk.

Barriers and How to Overcome Them

Of course, scaling from laboratory curiosity to industrial reality brings cost and supply questions. Many advanced materials stumble at the pilot stage because of complexity or rare raw materials. Open communication with suppliers and clearer understanding of synthesis routes can tackle some of these issues. Standard-setting organizations, like ASTM and UL, should move quickly to develop testing protocols, so manufacturers know exactly what to expect when adopting ionic liquids. Collaboration between academic labs, industry, and regulators helps keep everyone honest and drives real progress.

Looking Forward

Real breakthroughs happen when new materials meet specific challenges head-on. Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide stands out because of what it brings to battery safety, stability, and all the performance factors that engineers need. As battery tech evolves, keeping an eye on advanced electrolytes like this one ensures smarter, cleaner energy storage down the road.

What Is Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide, and Where Is It Used?

Anyone dealing with advanced chemicals usually stumbles on long names like trioxylmethylphosphonium bis(trifluoromethanesulfonyl)imide. It pops up most often in research labs, typically in battery development or specialty chemical synthesis. Chemists always love a powerful reactant that can push the limits of synthesis. This one stands out because it brings considerable ion conductivity and thermal stability to the table. But those scientific strengths rarely translate to being gentle on your skin or lungs.

Safety: No Room for Assumptions

It’s easy to underestimate the risks when you work with chemicals daily. Flashy phosphonium salts may look harmless in a bottle, but take them out in the open, and you’re looking at hazards that should be top of mind. This compound contains heavy-duty fluorinated sulfonyl groups and phosphonium ions. These parts signal real risks for irritation and even burns. Literature points to the fact that trifluoromethanesulfonyl groups often carry toxic and corrosive traits. Breathing even small bits of their dust or vapor, especially in a closed room, can lead to coughing, sore throats, and potentially serious long-term health effects.

What My Experience Says

In my own time running syntheses, one lesson always came through loud and clear: Fancy names don’t mean safer chemistry. More than once, I watched colleagues shrug off the warning because the powder didn’t smell, didn’t fume, and looked plain enough. Next thing, someone’s calling for help because of a splash or a spill on the bench. Working with phosphonium salts and perfluorinated chemicals taught me to double up on gloves and pay attention to splash goggles—every time. You mess up just once, and your hands or eyes are on fire for the rest of the day.

Company Data and Regulatory Guidance

Look at the safety datasheets from major chemical suppliers or academic safety offices. Their guidance often reads: wear nitrile gloves, go for chemical splash goggles, and handle everything in a fume hood. No arguing with the data; exposure to skin risks corrosive burns, while inhaling dust can cause respiratory symptoms that linger for days. Disposal calls for hazardous waste channels—no pouring down the drain. The data tie back to regulatory watch lists too. Both the US Environmental Protection Agency and European Chemicals Agency highlight the health and environmental risks of many trifluorosulfonyl family chemicals.

What Keeps People Safe

In real-world practice, lab workers can’t afford shortcuts. Step into a facility that respects chemical hygiene, and the basics stand out: fresh gloves, lab coats, fitted goggles, and well-maintained ventilated hoods. Users keep chemicals labeled, never leave spills for someone else, and alert safety officers the minute something happens. Training newcomers to take these habits seriously shapes a safety culture that protects every team member. I’ve seen entire projects stop cold because one person let down their guard.

Improving Chemical Safety

Better handling starts with teaching—not just about the hazards but also about solutions. Reliable online training, hands-on demonstrations, and frequent refreshers help embed good habits. Automated chemical inventory systems reduce the risk of accidental mix-ups. Where alternatives exist, seeking less hazardous substitutes supports a safer research environment without killing innovation.

Takeaway Lessons

Trioxylmethylphosphonium bis(trifluoromethanesulfonyl)imide is not the chemical to treat lightly. Its advanced properties can drive great science, but the price for complacency remains high. Staying safe requires respect for the risk, attention to proven safety routines, and a willingness to step away and reassess if something feels uncertain.

The Realities of Chemical Storage

Trioxylmethylphosphonium bis(trifluoromethanesulfonyl)imide doesn’t show up in every lab, but people who work with phosphorus compounds will recognize the risks. Unlike sugar or salt, this material doesn’t just sit on a shelf for a few months without making noise—humidity and heat have real consequences here. It calls for a close look at real storage habits: chemicals don’t read labels, but those mistakes come back to you fast.

Keep It Cool, Keep It Dry

Every chemist can tell stories about water-sensitive reagents gone bad. Trioxylmethylphosphonium bis(trifluoromethanesulfonyl)imide falls into that category, so open doors to moisture cost you money. Even trace water can set off decomposition, creating compounds you never asked for and sometimes sending strong odors through the whole building. In hot weather, temperature spikes speed up degradation, which means ruined stock, interrupted experiments, and safety questions you don’t want to answer. Simple choices make the difference—put the container in a desiccator or at least a tightly sealed jar with some silica gel. My own bench has seen too many damaged chemicals when people assumed “room temperature” meant the middle of summer or near a window.

Where Chemicals Meet Real-Life Risks

Some companies treat dry storage as a suggestion, not a rule. They regret it later. Water contamination has already cost the industry millions in lost batches and cleanup chores. On top of shelf-life worries, there’s the health angle. Once decomposition starts, handling waste takes more personal risk and invades the breathing space. Wearing gloves and goggles seems obvious, but people forget if chemical rules only exist on posters. A responsible lab keeps every reactive bag double-bagged—anyone getting casual with flammable or moisture-sensitive bottles invites disaster.

Fact over Fiction: Container Choices

Trace glassware scratches allow leaks or let in moisture. Even “sealed” vials can be misleading. Metal cans or bottles lined with inert material solve half these issues—less glass breakage, better seals. Nothing beats physically checking container seals every couple of weeks. Factor in the cost of spoiled chemicals, and you’ll see regular audits pay for themselves. Some labs also add container labeling with last opened dates and inventory logs, so nobody handles a bottle blind or discovers rotten surprises the hard way.

Inventory Turns, Not Just Storage

People sometimes forget: unused chemicals aren’t “safe” just because they haven’t moved. Old, poorly stored trioxylmethylphosphonium bis(trifluoromethanesulfonyl)imide can lurk for years, waiting to foul the air or eat through storage racks. Disposing of it gets complicated—hazardous material, regulatory paperwork, increased disposal costs. Labs and storerooms that plan ahead rotate inventory regularly and dispose of expired materials in small, manageable amounts, not in one terrifying “catch-up” sweep.

Building Better Habits

Proper storage boils down to clear communication and visible training. Teams that talk about storage rules out loud don’t fall back on bad habits. Posting reminders near the chemical cabinets, combining solid procedures with quick spot-checks, and building storage maps help both veterans and newcomers avoid expensive mistakes. Safe habits keep chemicals working the way you need them, protect people’s health, and stretch already-tight research budgets. It takes more than a line in a safety manual; it’s about daily choices made with eyes wide open.

What Chemical Stability Means for Everyday Users

People ask about chemical stability because it hits close to home—no one likes surprises with products that go bad before you expect. Take medicine in your cabinet or cleaning supplies under the sink. If a product starts breaking down, you lose trust, and in some cases safety can take a hit. Poisoning incidents or allergic reactions often start with someone using a product past its prime, not realizing that some key ingredients have changed along the way.

What Impacts the Stability?

As someone who has worked around industrial materials all my life, I've seen changes that heat, moisture, or light can bring. Most products do best if you store them cool and dry, but life’s not always that predictable. In my early years working at a small paint shop, I saw paint cans left open on humid days turn into sludge. That’s not just a waste of money; it means the paint’s not going to work. That’s chemical instability right there, something everyday people get hit with more than they realize.

Outside of consumer goods, chemical stability gets a lot of attention in the chemical and pharmaceutical industries. Regulations demand a certain shelf life, usually based on tests at high temperatures or in sunlight. Companies put in the work to give you safe instructions—“store below 25°C, keep away from sunlight”—because anything outside those limits could start changing the mixture inside the bottle.

Impact on Health and Safety

An unstable chemical isn’t just a losing value game, it can become dangerous. Take medicines—if aspirin or antibiotics start to break down, you might lose the benefit or end up with substances that actually harm you. Some cleaning products, like bleach mixed with acid-based cleaners, go unstable in seconds and create toxic gas. In my own kitchen, forgetting this lesson once left me scrambling for fresh air. Stories like these explain why paying attention to proper use and storage is so important.

Data from the U.S. Food and Drug Administration shows that around 3 to 4 percent of drug recalls happen due to problems with chemical stability. The American Association of Poison Control Centers has reported over 250,000 exposures linked to household cleaning products each year. Many of these cases involve people unaware of product limitations or changes after long storage.

What Can Fix the Stability Problem?

A lot can be done on both sides—producers and consumers. Some companies put stabilizers in their formulas so the active ingredients don’t fall apart easily. There are blister packs for pills, sensors for temperature in vaccine containers, and better instructions on labels. My advice for anyone at home: Stick to the storage instructions. Check expiration dates and avoid mixing chemicals unless the label says it’s safe. Buy smaller quantities you’ll actually use.

With everyday products, education and habit often make the difference. A little knowledge about the stuff you keep at home can save money and lower health risks. And for those of us in production, ongoing testing and better packaging help ensure people don’t have to discover instability the hard way. That kind of care keeps trust strong and lives a little safer.

Understanding the Stakes with Sensitive Chemicals

People working in research labs or chemical manufacturing know that shipping specialty compounds means far more than just sticking them in a box. Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide represents one of those highly reactive, moisture-sensitive substances scientists approach with serious care. One small mishap can endanger not only the product but entire teams and facilities. I’ve seen the results when a shipment arrived damaged: ruined inventory, wasted money, and a lot of unnecessary risk.

Materials that Do the Job Right

For anything this sensitive, glass bottles make the top of my list. High-density polyethylene gets considered sometimes, but glass stands up better to changes in temperature and holds up against aggressive chemicals. Anything with a phosphonium backbone reacts fast, so I’ve watched vendors use amber glass bottles with airtight PTFE-sealed caps. The amber blocks out harmful UV rays, a sneaky problem that often gets overlooked, and PTFE liners really keep out that persistent moisture that ruins everything.

That’s just the first layer. A secondary containment, wrapped with absorbent materials and sealed in sturdy metal cans, ensures if there’s any breakage, labs don’t open boxes of contaminated insulation foam. In my experience, this double packing means the lab techs and receiving departments breathe a little easier every time.

Temperature and Transport Conditions

Too many times, I’ve seen materials like this turn useless after a cross-country trip during the summer. I learned the hard way: refrigeration or cold packs make a surprising difference. The right vendors don’t just toss an ice pack in; they use temperature-logged boxes so every handoff gets tracked. Dry ice proves too aggressive sometimes (watch out for glass cracking), but gel packs with well-planned insulation keep things steady until the destination. Proper labeling—hazard diamonds and handling instructions—matters as much as the right packs, since it alerts everyone down the chain to treat packages with respect. I never assume my courier understands the risks unless the box screams “handle with caution.”

Compliance and Responsibility

Every shipment must clear tight regulations—DOT, IATA, and sometimes local laws. A trusted supplier stays on top of the rules, which often change without much warning. It helps to work with companies committed to Responsible Care protocols, because they keep paperwork in order and offer full traceability for every batch. I once worked on a joint project where customs seized a batch due to incomplete SDS documents: that three-week delay cost a fortune and soured a collaboration. Full documentation should ship with the compound, not just the invoice. This paperwork matters as much as the bottle itself.

Looking Toward More Sustainable Packaging

Single-use plastics and insulation fill too many landfills, and more labs ask suppliers to switch to recyclable or reusable packaging. Change feels daunting, since this isn’t just about switching brands of tape; the right materials keep people and product safe. Some companies try out insulated shippers made from recycled materials or redesign metal cans for re-use. These ideas save money in the long run and build trust—especially for organizations thinking about their environmental record.

Real Solutions Start with Strong Communication

Any team ordering critical materials like Trioxylmethylphosphonium Bis(Trifluoromethanesulfonyl)Imide has to build a good relationship with their suppliers. Picking up the phone beats clicking order buttons. Questions about shelf life, emergency response, and tracking matter, especially since the people handling these shipments rarely see the inside of the original lab. Investing in good packaging protects people first, and that mindset shapes better decisions for the entire process. In my career, those conversations prevented more accidents than any checklist ever could.