Trioxylmethylphosphonium Bromide: Navigating the Spectrum of Science, Industry, and Safety

Historical Development

Decades ago, chemists searching for new ways to manipulate molecular structures stumbled across phosphonium salts and became fascinated by their versatility. The roots of Trioxylmethylphosphonium Bromide's story track alongside advances in nucleophilic substitution and organophosphorus chemistry through the late 20th century. As the appetite for new organic synthesis tools grew, research shifted from bulk phosphines to more reactive and targeted compounds like this one, guided mostly by hard-won experience in laboratories. Teams in Europe and North America led the charge, publishing papers that documented both setbacks and breakthroughs, showing that error-prone processes slowly turned reliable by trial, error, and relentless tweaking. The knowledge didn’t stay locked in academia, either; specialty manufacturers soon took interest, initiating a steady march from glassware batches to bulk production.

Product Overview

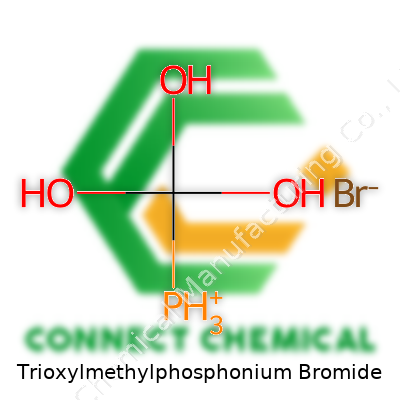

Trioxylmethylphosphonium Bromide reflects a class shaped by a precise marriage of reactivity and selectivity. In essence, this compound draws attention for the way its phosphonium core, paired with a bromide counterion, facilitates reactions that few other molecules can handle as smoothly. Researchers and manufacturers see value here because it works both as a reagent in the lab and as a building block for more complex intermediates. Once suppliers recognized consistent utility in several synthetic routes, it started showing up on catalogs under a range of trade names, sometimes with subtle tweaks to purity or particle form based on operational feedback from real-world users.

Physical & Chemical Properties

Users dealing with Trioxylmethylphosphonium Bromide can count on it typically forming a white to off-white crystalline solid, neither too volatile nor especially prone to clumping. Its melting point often lands above ambient room temperature, making handling straightforward with proper care. The compound dissolves best in polar organic solvents, thanks to its ionic nature and modest molecular weight. Stability holds up under cool and dry storage, but exposure to moisture or heat may compromise quality, especially in larger containers where the risk of cake formation rises. In reactivity, it shows strong affinity for nucleophiles, which underpins its starring role in certain substitution and coupling reactions, raising demand for high purity and finely controlled particle size from the chemical supply chain.

Technical Specifications & Labeling

Every drum or bottle reaching the marketplace displays a straightforward set of specifics: molecular formula, batch number, and impurity profile, with water content kept under a strict threshold. Labels call out the need for sealed storage and note the recommended temperature range, underscoring experience gained from years of complaints about degraded reagent. Certification sheets back up purity claims, but real trust comes from suppliers who answer questions about analytical methods or packaging right away, not after a week in limbo. Researchers and technicians alike rely on this clarity, using it to plan safe handling and ensure experiment repeatability.

Preparation Method

Synthesis begins with the reaction of trioxylmethyl or related intermediates with triarylphosphine compounds. This step requires careful temperature management and asks technicians to keep a close eye on stoichiometry. The addition of hydrobromic acid or a comparable bromide source swings the reaction toward the desired final product. Scientists learned that subtle tweaks—like slow addition of reactants or prolonged stirring—make the difference between useful yields and unusable sludge. The final isolation happens through crystallization or solvent precipitation, both routes leaving minor but critical residual solvents that need careful removal. Tales abound of entire batches lost to hasty washing or premature drying, reinforcing the premium on methodical refinement and repetition in the production hall.

Chemical Reactions & Modifications

What truly makes Trioxylmethylphosphonium Bromide popular among synthetic chemists is how it facilitates transformations under surprisingly mild conditions. It can transfer its methyl group to nucleophilic substrates, making it invaluable in methylation or the introduction of certain protecting groups. This reactivity produces both desired products and trace byproducts, so chemists constantly search for cleanup strategies that don’t add hours to purification. Over the years, industry veterans discovered that additives or precisely tuned temperatures alter selectivity, and sometimes, introducing a co-solvent delivers rewards in higher yield or cleaner profiles. In specialized settings, modifications flip the bromide ion for another halide, tweaking the reagent’s selectivity or safety characteristics.

Synonyms & Product Names

Buyers encounter this compound under a handful of synonyms—everything from its proper IUPAC name to trade labels from specific suppliers. Catalogs display names like Trioxymethylphosphonium Bromide, TMPB, or variations depending on whether it’s being marketed for research or large-scale manufacturing. For regulatory compliance and safety documentation, the most systematic name always wins out. Disagreements over naming occasionally trip up less experienced folks, but tech support from suppliers often bridges the gap by translating between jargon-heavy certificates and more familiar shorthand. The lessons shared among users typically boil down to: always double-check the certificate of analysis before committing to a scale-up.

Safety & Operational Standards

Safety practices in dealing with this compound trace lessons learned from past close calls and missteps. Contact with eyes or skin can cause irritation, so lab veterans rarely work without goggles and gloves. Ventilated hoods reset as standard after accidents with fumes. Companies invest in periodic safety audits and training refreshers, having recognized that the risks of bromide exposure—like respiratory effects or sensitization—carry serious repercussions. Spills prompt quick cleanup with inert absorbents, and residues never go down standard drains. Transport regulations require proper labeling and secure packaging, with incident logs from bulk handlers showing that those who cut corners end up paying more in lost product or fines. Toxicology studies underpin much of this operational discipline, pushing handlers toward best practices that keep teams and neighborhoods safe.

Application Area

Demand for this reagent spans both academic and industrial settings. Medicinal chemists harness its ability to enable late-stage functionalization of drug candidates, giving pharmaceutical pipelines added flexibility. Polymer specialists find its chemical profile fits certain cross-linking schemes, creating structures with unique electronic or thermal properties. In manufacturing, it gives options for rapid, one-step transformations, making it popular in pilot plants and kilo-scale workshops. The breadth of application ensures a steady stream of feedback and improvements, as each new field asks for tweaks in purity or form that, in turn, spur innovation in synthesis and quality control.

Research & Development

Academic groups stay keen on this compound, viewing it both as a teaching tool and a workhorse for expanding the repertoire of phosphorus chemistry. The quest for greener chemistry has researchers evaluating less hazardous routes to both its synthesis and its safe disposal. Some labs have tested alternative bromide sources or swapped traditional solvents for those that cut waste or toxicity, gaining ground without sacrificing performance. On the corporate side, R&D teams run aging studies to extend shelf life and examine ways to scale production without producing more byproducts. Journals fill with case reports describing new coupling reactions or tailored surface modifications achieved with optimized versions of this classic reagent.

Toxicity Research

Toxicologists started with rudimentary animal tests, then moved quickly to mechanistic studies at the cellular level. Their results show clear thresholds for safe exposure—defining limits that influence everything from warehouse storage to worker shift rotations. Experience proved inhalation or prolonged skin contact can lead to irritation or more serious outcomes, and chronic exposure studies flagged some risks that led to tighter regulatory scrutiny. Producers launched collaborations with occupational health experts, designing monitoring programs and emergency protocols. Toxicity findings filter down into every practical guideline, creating a knowledge loop where science and real-world practice constantly influence each other. The data repeatedly highlighted the need for continuous review as new findings emerge from long-term monitoring.

Future Prospects

Looking ahead, this reagent seems poised to move beyond its traditional strongholds. As industries push for more atom-efficient syntheses and fewer waste streams, developers explore whether this class of reagents can fit into sustainable chemistry initiatives. Robotic screening platforms now scan libraries of similar phosphonium salts, chasing candidates that deliver equivalent performance but break down into even less hazardous byproducts. Startups aim to commercialize variants tuned for renewable feedstocks. Regulatory agencies keep revising guidelines as more toxicity data surfaces, shifting the ways companies approach product stewardship. In every sector that touches this compound—pharma, materials, advanced research—a cycle of shared experience continues, with each experiment nudging the boundaries of what these reagents can accomplish while maintaining a hard focus on safety and responsible innovation.

Chemistry at Work in Modern Synthesis

Trioxylmethylphosphonium bromide shows up in labs and chemical factories because of its punch as a reagent. Chemists lean on it when they need to transform alcohols into alkyl bromides. The reaction tends to run smoothly, giving results even when the substrate carries other sensitive groups. Growing up around a family member who worked in a chemical plant, I heard stories about the push for more reliable ways to get key intermediates with fewer surprises. Trioxylmethylphosphonium bromide landed on the bench for this reason. It brings results where some older, harsher reagents might overreact or give funky byproducts that slow things down.

The Draw of Selectivity and Simplicity

Many routes in organic synthesis hit a snag when other pieces of the molecule don't want to leave each other alone. Trioxylmethylphosphonium bromide steps in because it doesn't bully the whole molecule—just the alcohol group. You end up with an alkyl bromide, ready for further transformation. Drug developers use this to assemble building blocks, aiming for fewer steps and cutting out purification drama. My own brush with undergraduate organic chemistry showed how a smoother, more targeted reagent keeps everyone happier, especially at scale.

Meeting Pharmaceutical and Material Demands

Factories pumping out drug ingredients or specialty chemicals run on efficiency. Picture a drug lab working late into the night: researchers crave consistent yields, tight control, and fewer headaches. Trioxylmethylphosphonium bromide enables this, creating reliable connections that matter in pharmaceutical development. Fact sheets point out its stable shelf-life and ability to work in various solvents. Simple logistics count for a lot when deadlines and budgets press. The shift toward greener, scalable chemistry gives this reagent even more appeal, since it often means less leftover mess and more recoverable product.

Safety and Challenges

Working with phosphorus-based reagents calls for respect. Accidents create delays or worse. Chemists use hoods, gloves, and goggles, keeping water and air away since the compound might react or degrade. Like many effective chemicals, Trioxylmethylphosphonium bromide needs sharp attention to waste disposal, as regulations about phosphorus waste tighten across Europe and North America. In my conversations with compliance officers, the theme remains the same: safety must stick with speed. Knowledge and training walk hand-in-hand with the adoption of these strong reagents.

The Road Forward

Newer labs look for tools that save time, cost, and stress. Trioxylmethylphosphonium bromide fits this bill, and its use spreads with increased investment in contract manufacturing and green chemistry. For young chemists, learning how to handle reagents like this responsibly can open doors to advanced synthesis and pharma jobs. Research keeps pressing for even milder, safer alternatives, but right now, this compound stays relevant in places where getting bromides from alcohols supports fast, reliable product pipelines.

Building Trust Through Science

Solid experience, published results, and safety audits all back up the growing role of Trioxylmethylphosphonium bromide. Those who use it watch for updates in best practices and push for cleaner processes as regulations shift. The lesson here comes down to blending smart chemistry with trusted oversight, meeting both immediate business goals and the future’s tightening standards.

Understanding Safe Storage

Many research labs and industrial spaces rely on Trioxylmethylphosphonium Bromide for specialized chemical synthesis, especially where precise phosphorus chemistry comes into play. From personal experience working with similar organophosphorus compounds, improper storage can spell disaster—putting equipment, data, and health at risk. The hygroscopic nature of this compound means it soaks up moisture from the air quickly, breaking down and often losing its potency. Long-term exposure to room humidity creates clumps that clog weighing tools or cause inconsistent results. For this reason, laboratories turn to air-tight, moisture-free containers, topped with secure screw-caps or sealed jars and the added insurance of desiccators.

I remember how carelessness led to a ruined batch that left our team scrambling to source fresh material and redo months of careful work. Even an innocent lapse like leaving the lid loose for an afternoon forced us to rethink our inventory approaches. So many accidents and exposures happen not with big spills, but when daily vigilance slips.

Temperature and Chemical Stability

This compound stays stable at cool, constant temperatures. Store it well below 30°C, but never too close to freezing since condensation might form on surfaces during temperature swings. Refrigeration works only if protected from frost and moisture. Setting a dedicated shelf or section of the fridge, separated from food or perishables, is not just a regulatory checkbox but a practical safeguard for staff health.

Heat breaks down the chemical bonds in Trioxylmethylphosphonium Bromide, creating by-products that not only waste expensive reagents but may increase risk. High-storage temperatures often spell increased volatility, fumes, or accidental releases, which add stress to already busy research settings. Monitoring regularly with fridge thermometers or even simple data loggers gives peace of mind and helps catch subtle shifts before damage happens.

Protecting Workers and the Environment

Many overlook handling issues until a near-miss or spill shakes everyone awake. Gloves, splash goggles, and lab coats represent basic protection, but the real defense comes through strict habit. Never scoop directly from shared jars—use secondary vessels, never touch containers with wet hands, always work in low-airflow zones. Emergency showers and eyewash stations stay ready, not dusty or blocked. Supervisors must reinforce this, since familiarity breeds shortcuts; even experienced chemists fall prey to casual mistakes.

Trioxylmethylphosphonium Bromide never belongs near food, water, or break rooms. Any release or spill gets cleaned up with an absorbent pad and sealed in hazardous waste. Never dump leftovers downstream or in regular trash. Many institutions, ours included, keep a running log of chemical movement, disposal, and storage checks—simple measures that catch both practical and compliance issues long before regulators come knocking.

Building Safer Habits

Good storage and handling start with honest training and clear protocols. I have seen the strongest lab cultures focus on routine, not just emergency muscle memory. Label all bottles with opening dates and review stock rotation schedules monthly. If using it for larger-scale synthesis, set up single-use aliquots so main stocks remain untouched. Always document any temperature excursions, and inspect containers often for cloudiness or crust indicates moisture breach.

Most importantly, peer reminders and open communication carry more weight than any written rule. By putting safety on the daily agenda, accidents drop, materials stay fresh, and science moves forward—without preventable setbacks.

What Is Trioxylmethylphosphonium Bromide, Anyway?

Trioxylmethylphosphonium Bromide sounds like something pulled straight from a chemistry textbook, and that’s not far off. Labs and industries use it as a reagent, especially for making other chemicals. Most people never see or touch it, but those working around it recognize its strong reactivity. Turning powdered substances into new things takes more than know-how—it calls for respect for the chemistry involved.

Hazards Nobody Wants to Learn The Hard Way

Contact with Trioxylmethylphosphonium Bromide brings risks. The main concern centers around toxic effects on the skin, eyes, and respiratory tract. This isn’t a household cleaner that causes mild irritation: even small spills or airborne dusts create problems. People handling it can develop rashes, burns, and coughing fits if safety gear falls short. A mistake like forgetting goggles or skipping a fume hood already means a bad day.

A fact that sticks out: its toxicity extends to the lungs. Inhalation may lead to inflammation, or, at higher exposure, more serious pulmonary issues. NIOSH and OSHA label chemicals with these risk profiles for a good reason: the margin for error runs thin. It takes only a misplaced glove or missed mask to cross the safe line.

No Use Ignoring Fire Risks

Not every reagent demands a firefighter’s attention, but Trioxylmethylphosphonium Bromide reacts with water, making dangerous gases. That means a small spill near a water source or humid environment can quickly shift from a mess to chaos. On top of that, many phosphonium salts burn easily, so keeping flames and sparks away isn’t just a good idea—it’s a must. Nobody in a lab with experience shrugs off flammables or reactive chemistries.

The Ripple Effect: Environmental Impact Matters

Disposal practices for chemicals speak to more than company policy—they show how much care people have for the world outside. If Trioxylmethylphosphonium Bromide enters water systems, wildlife and crops could face setbacks from contamination. Phosphorus-derived compounds sometimes stay in the environment for years, affecting food chains and even water quality. Researchers tracking chemical spills and improper disposal draw clear lines between accidents and long-term local harm.

Staying Safe: Where Solutions Start

Training helps remove a lot of fear from handling tough chemicals. Folks who think of PPE—gloves, rated goggles, and well-fit masks—as a hassle should talk to people who’ve dealt with burns or lung injuries at work. Ventilation systems, such as fume hoods, save lungs and reduce stress for everyone who shares the lab. Stores for chemicals like Trioxylmethylphosphonium Bromide must be dry and secure, never crowding it next to acids or bases—chemists often recall stories where shortcuts spelled disaster.

Transportation offers its own challenges. Labels matter, and emergency plans belong at hand. National and local authorities have made rules for shipping chemicals like this because even a small container, poorly packed, can start an emergency on the road.

The Human Element: Why This Conversation Counts

People worry about new chemicals flooding the environment or ending up in products close to our daily lives. That’s fair. One chemical accident costs resources, health, and sometimes lives. The lessons learned reinforce the need for transparency, access to hazard data, and public trust. The best labs and companies set strict rules, run drills, and prep for worst-case scenarios—not out of fear, but out of responsibility.

Nobody can pretend away the risks of Trioxylmethylphosphonium Bromide. Understanding and respect—backed by science, training, and proper gear—do much of the heavy lifting. Public awareness drives improvements and can keep companies honest. Everyone wins when the focus stays on well-earned safety instead of shortcuts.

What’s Behind the Name?

Trioxylmethylphosphonium bromide rolls off the tongue about as smoothly as sandpaper, but it’s a straightforward compound at its core. You see, its chemical formula is C4H10BrOP. Each molecule stacks up with four carbon atoms, ten hydrogens, a bromide, and the central phosphorus and oxygen. That formula alone tells a lot about how this compound interacts in labs and industry settings.

Purity: Why the Numbers Count

You won’t find many shortcuts in chemical research—impurities in something like trioxylmethylphosphonium bromide can change everything. From my time working with specialty chemicals, a batch even a couple percent off in purity can throw off lab reactions or industrial processes. Most reputable suppliers offer it at 98% or higher purity, but for serious applications, scientists aim for 99% and up. Labs push for such high benchmarks because traces of other molecules might gum up a reaction or create unknown byproducts.

Applications Rely on Precision

The chemical shows up most often in research as a reagent or intermediate. That means it helps pull together more complex reactions, such as introducing a phosphonium group to another compound. Folks in pharmaceutical labs, organic synthesis, and even some chemical engineering firms work with it because of its reactive profile and the clean transformations it can trigger.

I remember talking to a colleague who’d spent days hunting down a stubborn contamination issue. The source? An intermediate like trioxylmethylphosphonium bromide that clocked in at 96% instead of 99% purity. A small slip like this set back their research timeline and led to a lot of extra troubleshooting.

Supply Chain and Quality Control

Finding a batch at the right purity comes down to trusting your suppliers and knowing where materials are sourced. Different manufacturers use different cleaning and crystalization methods. Some labs even go so far as to test incoming reagents with their own NMR, HPLC, or GC-MS runs to double check what they’re getting. You want a supplier who’s open about their production process and ready to provide solid certificates of analysis.

Safety and Handling

This compound doesn’t show up in everyday life, but anyone using it should stay sharp. Trioxylmethylphosphonium bromide won’t make headlines for being explosive or wildly toxic, but proper lab safety remains non-negotiable. Gloves, goggles, and a well-ventilated fume hood belong in every protocol. If a spill happens or someone gets exposed, follow emergency procedures and have the safety data sheet close by.

Chasing Fewer Impurities: Path Forward

There’s always room to tighten up the chain from synthesis to shipment. Investing in better filtration equipment or working with third-party analytical labs for verification seems like a no-brainer. Sometimes it’s just about keeping communication lines open across the whole supply path. More transparency means fewer surprises in the flask and better outcomes for end users.

Final Thoughts

Trioxylmethylphosphonium bromide might sound obscure, but its formula and purity echo what’s important across chemistry—accuracy and dependability. Whether you’re working a research bench or running a pilot plant, these numbers matter. Stick to trusted sources, check certificates, and make purity a priority every time you crack open a jar of anything with a name this long.

Understanding the Risk

Trioxylmethylphosphonium bromide isn’t something you find in your kitchen cupboard. In my lab days, we always saw this chemical handled with thick gloves and a great deal of respect. On paper, it sits on several hazardous substance lists, flagged for its strong reactivity and toxicity. Breathing in its dust can harm lungs and eyes. Touching it without gear? Angry red skin and worse.

Ignoring the health warning is a fast way to regret. At one university, we once watched a careless disposal trigger a small evacuation. That lesson stuck with everyone: respect what you’re tossing out. Disposing of something this potent calls for real planning, not shortcuts down the drain or into the regular trash can.

Why Proper Disposal Matters

One flask down the sink might not seem like much, but chemicals like this don’t vanish with water. Bromide compounds travel—lingering in water systems and soils, affecting fish and even turning up in crops. I’ve seen old labs get fined years after they closed, after a pipe inspection turned up chemical residues miles away. Environmental damage piles up slowly. Regulators won’t look kindly on “just this once.”

Even outside the lab, janitors or waste handlers pay the price when they’re exposed by accident. One time, an unmarked bottle made its way into landfill prep, burned a worker, and kicked off lawsuits. Nobody likes paperwork, but the alternative—health emergencies, regulatory trouble, poisoned wildlife—brings much worse headaches.

Best Practices from the Field

Safe disposal happens well before someone asks, “What do we do with this?” We always trained new staff to label every container, no exceptions. Mixing unknown stuff spells disaster. Segregating waste—separating organics, inorganics, reducers, and so on—makes the job much safer. Every competent site keeps up-to-date Material Safety Data Sheets on hand, and everyone who touches the chemical learns the rules.

Disposal routes for something like trioxylmethylphosphonium bromide have one safe answer: certified chemical waste companies. These outfits know what to do, because their workers see the results of chemical neglect. Thermal treatment (incineration in high-tech facilities) tends to be the preferred method. Some sites might opt for chemical neutralization, but only with careful protocols and proper fume extraction. In my experience, even the toughest old-timers refuse to DIY disposal for this class of material.

Building a Culture of Responsibility

Ongoing training and clear documentation set the foundation. I remember a workshop where an older chemist shared horror stories from decades ago—chemicals chucked out windows and buried in car parks. Now, labs keep detailed waste logs. Students learn right off: no sneaky shortcuts, no blind-eye tossing. Inspections may seem strict, but they exist for a reason, considering the ugly fallout of ignoring them.

Ultimately, handling trioxylmethylphosphonium bromide as industrial or hazardous waste, using certified handlers, makes disposal straight-forward, safe, and legal. For anyone using it, that’s the price of admission to a modern lab—and the most basic respect for your coworkers and planet. Mistakes make headlines; careful disposal never does.